EZ Dock Life

EZ Docks don’t

sit on the water,

they become part of it

Hydro-Static

Surface

Tension

EZ Dock technology uses the water to its advantage to maintain flotation and a stable platform during fluctuation. The stance of EZ Docks is continually adapting to changes in water movement and level. EZ Dock flotation technology combines the active suction pressure of water on a platform being forced down. Think of it like taking a glass and pushing it down into a sink full of water.

The underside of EZ Dock features several air chamber columns. As the dock stands in the water air is trapped in these Pylon Chambers, creating a powerful suction force between the dock and the water. The second part of the stability design is the wake muffling perimeter. The cutout coupler positions serve a second function. They allow water to pass through the dock, as opposed to simply receiving the impact. This wake absorption technology permits the dock a consistently still water stance whenever the surrounding waters are turbulent.

3 Components

Drive EZ DOCK

Performance

Each component of the EZ Dock system plays a role in helping achieve its superior float stance. Each design element is continually acting on the others to maintain stability and resist shock. It can’t just float - it has to be purposefully active with the surrounding environment.

3-Piece

Coupler

Connection

The Coupler system keeps thousands of pounds of EZ Docks in-line, and protects against the consistent shock from water wake, current, chop, and fluctuating levels.

Roto-Mould

Polyethylene

Structure

The single mould polyethylene design was built with longevity in mind. They are resistant to breakdown, and have been third party tested to an estimated 40-100 year lifespan. They’re also recyclable.

Pylon

Air-Chamber

Stabilizers

The pylon truss air compartments and wake muffling design of EZ Docks enable it to maintain a consistent freeboard height and stable stance regardless of water conditions.

The Most Versatile

Floating DOCK System

EZ Docks - and its system components - were imagined, designed, and created with a mission of sustainability. EZ Docks are recyclable - and will NOT be a landfill item. They also have virtually zero impact on the natural environment they inhabit. The coupler connectors are actually manufactured with the remnants of recycled and repurposed tire treads. For real!

Float Capacity

-

454 kg

1,000 lbs. -

907 kg

2,000 lbs. -

1,361 kg

3,000 lbs. -

1,814 kg

4,000 lbs. -

1,451 kg

3,200 lbs. -

340 kg

750 lbs. -

454 kg

1,000 lbs.

Dimensions

-

1.02 m Wide X 1.5 m Long

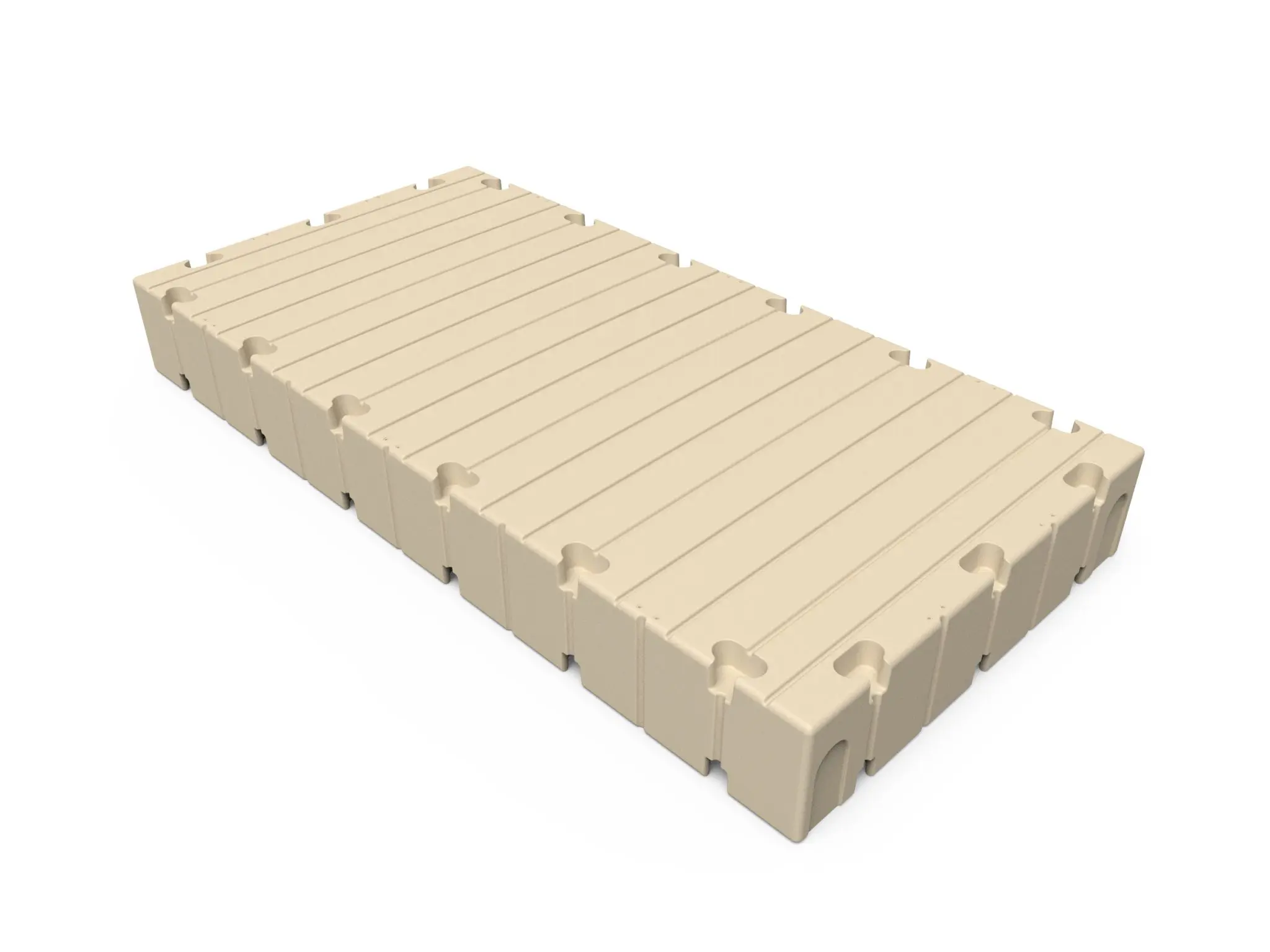

40” Wide X 60” Long -

102 cm wide X 3.05 m

40” (inches) Wide X 10’ (feet) Long -

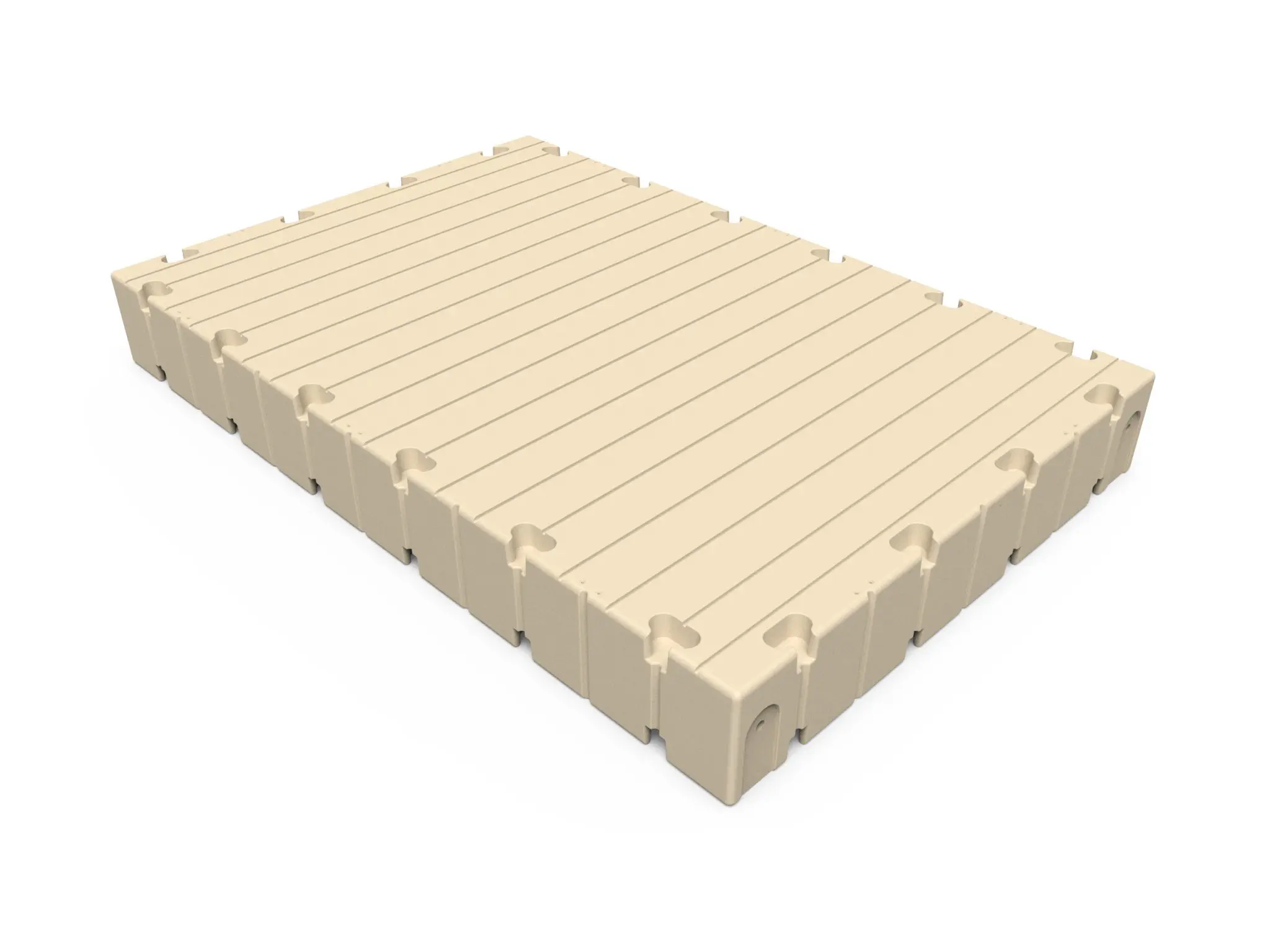

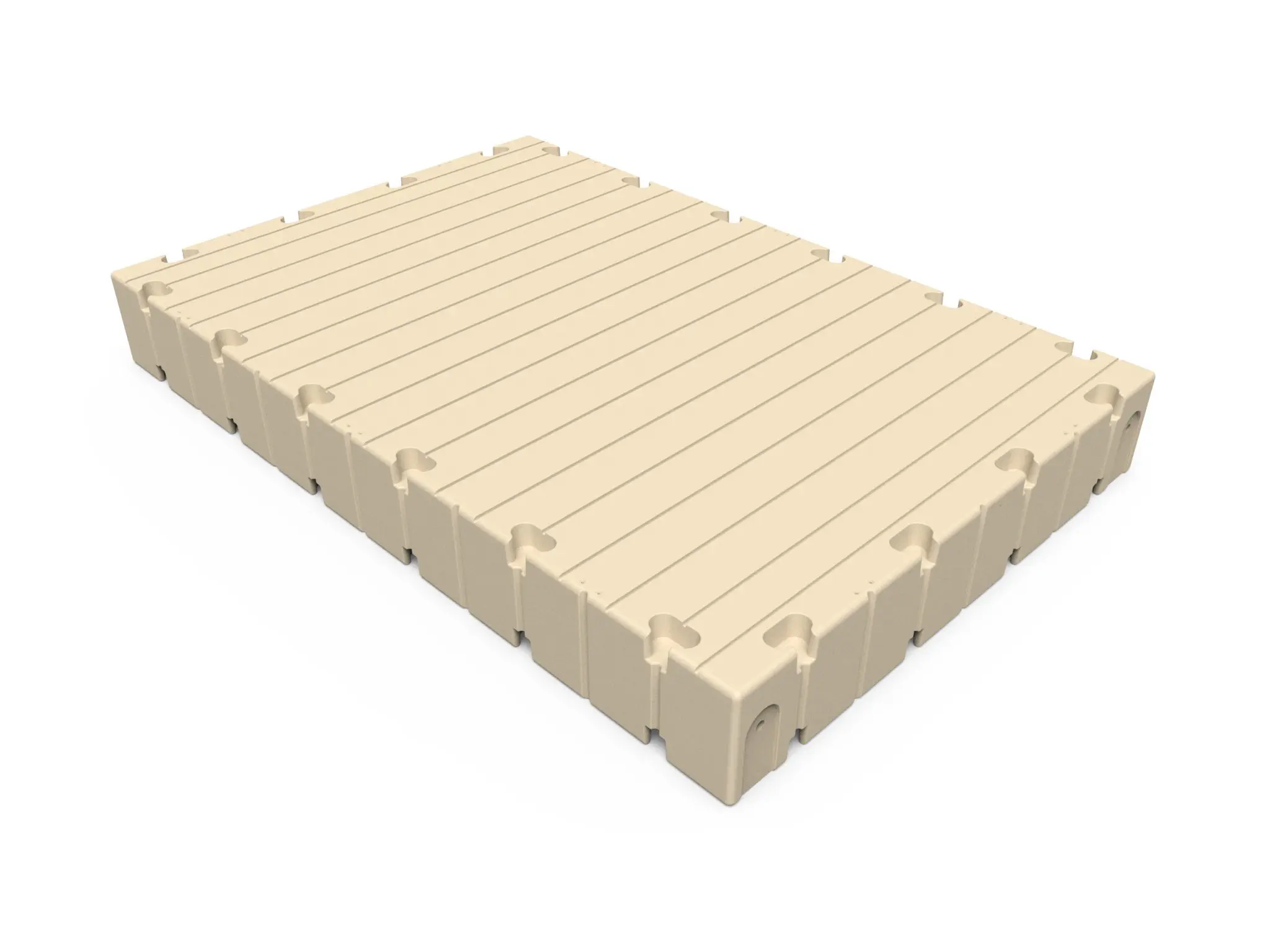

1.5 m Wide X 3.0 m Long

5’ (ft) Wide X 10’ (ft) Long

-

2.0 m Wide X 3.0 m Long

6’ 1/2” (ft) Wide X 10’ (ft) Long

-

2.0 m Wide X 2.5 m Long

6’ 1/2” (ft) Wide X 8.3’ (ft) or [ 100” ] inches -

1.5 m X 1.5 m X 2 m

58” X 58” X 80”

-

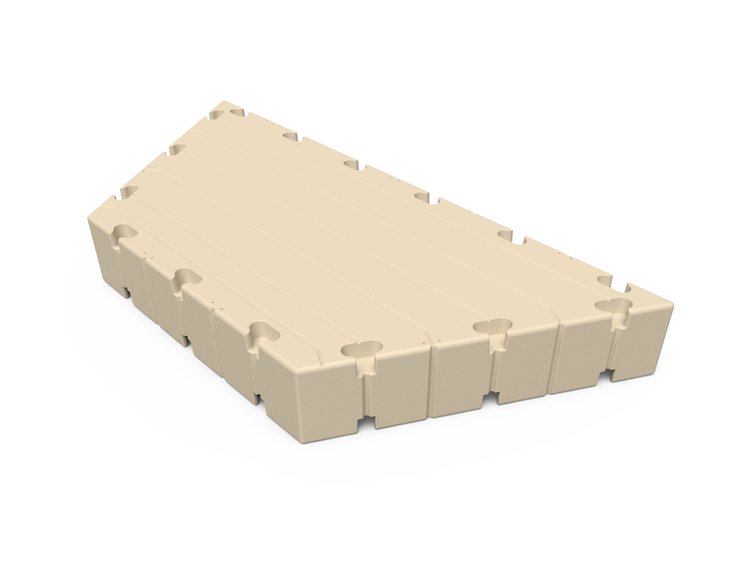

2 Sides Make the Swim Platform

3.0 m Long side - 1.5 m Short side

120” Long side

60” Short Side

Specs

-

Each EZ Dock is designed with a height of 38 cm (15 inches).

The water stance is just under 2 inches below the surface and just over 13 inches above the surface. -

Low Density Marine Grade Polyethylene

-

EZ Docks have an exceptional lifespan, but when it’s time - the materials used are recyclable.

The coupler connects used in the EZ Dock system are made from recycled material. -

EZ Docks contain nothing but air within the self contained mould - nothing else.

-

EZ Docks do not invade ecosystems or inhibit the surrounding environment. EZ Docks are designed to allow life-feeding sunlight to pass through to nourish the wetlands that support wildlife.

Customer

FAQ’S:

EZ

DOCK

-

EZ Docks are constructed of high-grade marine polyethylene. The roto-mould process creates a ⅜” thick, self-contained single section containing no inner materials except air. This design produces an exceptionally strong floating dock that is also extremely resistant to puncture or damage from the elements. The components that comprise the EZ Dock system are its coupler system - made of compressed vulcanized rubber, and the dock sections - built of incredibly strong, layered polyethylene compound.

-

EZ Docks’ pylon truss cavity design utilizes the scientific principle of hydro-static tension (suction beneath the surface) to achieve the strongest connection possible. EZ Docks essentially become a part of water as opposed to riding the surface uncontrolled. The wake-muffling pockets around the perimeter aid this stability by allowing water to pass through without interrupting the sealed connection to the water.

-

EZ Docks were put through rigorous third party laboratory testing to measure their durability against degradation and breakdown from environmental factors over time. The tests mimicked the wear and tear that would likely occur in the elements over a 40 year timeline. The results confirmed no existence of measurable breakdown or disintegration of material. They concluded the EZ Dock product to be the safest environmental dock system with the lowest cost of ownership.

-

This depends on placement and environmental factors where the dock is situated. EZ Docks (like many floating dock systems) were designed to be easily removed when required. This is a feature that makes them desirable. Like any investment in a product, you should want to protect its longevity. Any dock is safer when removed during the winter season. There are some exceptions; like small bodies of water (ponds or artificial lakes) areas with no ice, or very minimal current.

-

In keeping with the key design aspect of EZ Dock - versatility - engineers put a great deal of thought into how they could be anchored. EZ Dock systems boast an array of anchoring options to facilitate connection to virtually any type of waterfront or existing platforms. Each option serves a specific purpose and is designed to maintain the industry-leading stability of the EZ Dock system.

Dock System

Questions?