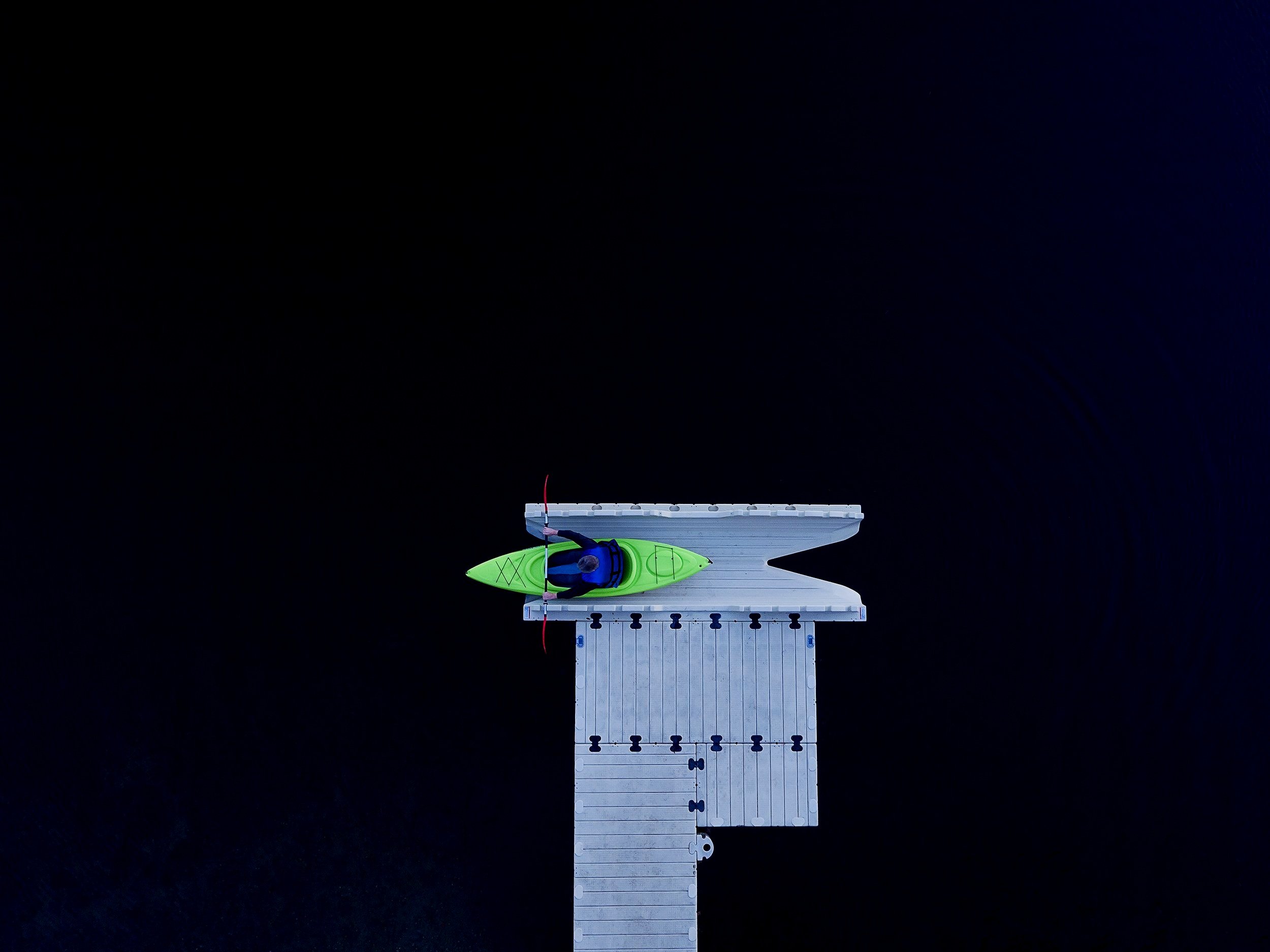

How does an EZ Dock

actually work?

EZ Dock

Technology Leverages Science

Recycled Rubber

Modular Polyethylene

P = pgh

That’s How

Coupled Together

Float Independently

The First design component that enables the strength and flexibility of EZ Docks is the rubber couplers and nylon composite connection system. 2 tapered coulplers are used atop and beneath the dock - connected via a rod and nut. Each coupler can capture and disperse up to 4,000 lbs. of torsion (twisting) pressure each time the docks are impacted. When the docks encounter chop or inclement weather - shock energy is transferred from the docks to the couplers where it is absorbed and redistributed away from the system. This energy dispersal is essential to keeping the dock from experiencing wobbles or instability of any kind.

Single Piece

Roto-Mould

Polyethylene

The Second design element is the dock itself. Each piece is made as a self-contained single mould LLDPE (linear low-density polyethylene) section encasing nothing but air. Each dock has a modular connection perimeter that doubles as wake muffling channels and connector seating. EZ Docks feature 3/8” thick roto-moulded walls and cut-out air chambers that enable its hydro-static float technology.

Flexible Anchoring

Makes the

Science Possible

The third design component that enables EZ Dock’s strength and flexibility is its two-way anchoring. Every EZ Dock anchor option keeps the dock secured to the desired platform, while allowing it to float freely and respond to the elements; as it’s designed to do. EZ Dock anchoring has yet to meet a challenge for which it did not have the right tool. Water runs the show - when it comes to floating docks. Without an anchoring system that holds position while allowing the dock to move whenever necessary - you’ll always be paddling upstream..